Allows you to see things that are invisible to the eye and reveal problems, this thermal camera is a simple to use, dependable tool that your team can rely on. Features a 320 x 240 resolution for the clarity and image detail you need, along with a 9 Hz frame rate.

See the problem and the location in one image with IR-Fusion™ technology

IR-Fusion technology, automatically captures a digital visible light image at the same time as an infrared image. The camera blends the two images together, pixel for pixel, in a single display. You can then view the image in full infrared, full visible light or at several degrees of blending in between. The location of an infrared target can be precisely identified even if the infrared contrast is low and there is very little structure in the infrared image

What’s included with the Fluke TIS60+ 9HZ

- Thermal Camera

- 4 GB Micro SD Card

- USB Cable

- Rugged, Hard Carrying Case

- Soft Transport Bag

- Adjustable Strap

- AC Power Supply (Including Universal AC Adapters)

- Two-Bay Smart Battery Charger

- 2 x Lithium-Ion Smart Batteries

The importance of image quality in thermography

When conducting infrared inspections, high quality images that allow for better analysis, presentation and professionalism are essential.

With a sharply focused image, there is a distinct contrast between areas of varying thermal energy on the surface being inspected. This allows the individual detector elements (also known as pixels) to clearly report the intensity of the energy being focused on them.

When the focus is poor, the incoming energy isn’t as concentrated on individual detectors, and their response is skewed. This can lead to temperature measurements that are significantly off, resulting in expensive downtime and possible safety hazards.

Thermal imagers are made with 100% diamond-turned germanium lenses covered with a specialty coating, providing premium quality images.

Easily choose and focus on your target

LaserSharp™ Auto Focus uses a built in laser distance meter that provides both speed and precision. The laser-driven target detection pinpoints the target while the camera focuses to capture a precise, high quality image. With LaserSharp Auto Focus, you can:

- Easily capture high-quality, focused images of your desired target with the push of a button

- Take infrared images through common obstacles like chain link fences

- Avoid skewed temperature measurements by precisely choosing your target

- Perform the same inspections multiple times as a part of your preventive maintenance program – the built-in laser distance meter calculates and displays how far you are from your target, making repeatability much easier

Choose multiple targets at different distances

MultiSharp™ Focus takes multiple images from different focal distances and combines them into one clear image. With a simple point and shoot, you can go from being completely out of focus, to complete focus, throughout the field of view. With MultiSharp:

- Reduce the need to take individual images of targets that are in the camera’s field of view – focus on one target, and all objects that are in the camera’s field of view will be in focus

- Cut down time spent taking multiple images to increase productivity

- Capture quality, in-focus images, even under direct sunlight

Shoot from a distance

Infrared inspections can take you into multiple types of environments with many types of equipment. Interchangeable lenses that require no calibration give you the versatility and the image quality needed to conduct inspections in almost any environment.

- Reduce the need to enter the danger zone with a 2x telephoto lens

- Identify potential issues as small and distant as a failed splice on a high electrical line from the ground with a 4x telephoto lens

- Save time with roofing and industrial building inspections by viewing a large area at one time with a wide angle lens

Easily manage and analyze your data

Document information on the equipment you’re inspecting

With IR PhotoNotes™, voice or text annotation, you can easily document critical information about each piece of equipment and its location. Each “note” attaches to the image, so you never have to search or match up notes to images.

- Document critical information with your infrared image

- Capture surrounding details like wind conditions and time of day

- Identify asset location

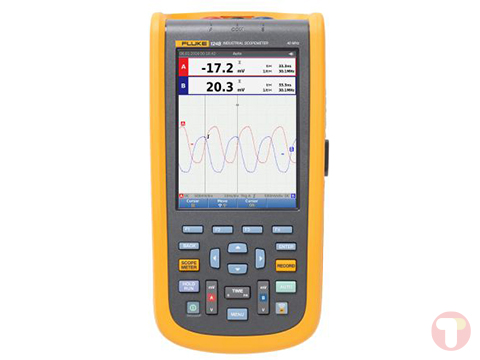

Capture digital and infrared images at once

IR Fusion™ technology combines a visible light and an infrared image into one, giving you better clarity.

- Get exact location details in picture-in-picture mode, which provides the center part of the display in IR and the remainder of the image in visible light

- See more details when you adjust the level of infrared and visible light blending in AutoBlend™ mode

- Isolate problem areas with user-defined temperature ranges with IR color alarms

ROI and thermal imaging

Seven benefits of on-site infrared inspections

- Reduce downtime

Inspections can be done while equipment is running – no lost production time. - Protect lives while doing more

The non-contact nature of infrared inspections allows technicians to scan large areas quickly, from a safer distance away. That means technicians can inspect more equipment faster. - Improve production efficiency

Subtle problems are found and addressed before they have a major impact on production. - Document before and after

Validate post-maintenance work and capture the results for future review. - Reduce capital expenses

Finding and repairing problems at an early stage can improve the life expectancy of equipment, as a result extending replacement intervals. - Increase productivity

Quickly scan a large area to find air leaks, insulation gaps, moisture and overheated electrical components to complete more work in less time. - Identify work in easy-to-understand terms

See exactly what the problem is on the camera, eliminating guesswork and making it easier for everyone to see what repairs needs to be done.